Blades and Saws

Shears

Various types of shears are widely used in rolling mills.

MWE supplies the following types of shears:

- Flying shears (crank or crank-lever) on a rolling mill;

- Shears for cutting wire rod on high-speed rolling;

- Shears for cutting the workpiece along the length of the refrigerator;

-

Shears for cutting rolled products to the length of the finished product:

- stationary cold cutting shears,

- flying cold shears combined with straightening machines.

Shears for cold profile cutting

Stationary profile shears are the alternative to using cold saws or cut-off machines. With a cutting force of 6300 MN, the shears are capable of cutting large profiles and solid cross-sections. The patented cutting system allows you to achieve cutting properties similar to saws or cut-off machines, even when working with beams.

Due to the high frequency of cutting, it is common to install only one pair of shears instead of 2 or 3 cutting machines.

Unlike cutting machines, wear on the cutting blades in shears is minimal.

Technical characteristics

|

Cutting force |

6300 MN |

|

Blade length |

1000 mm |

|

Cutting stroke |

240 mm |

|

Cut/hour theoretically |

360 |

Fast shears for cutting of steel bars

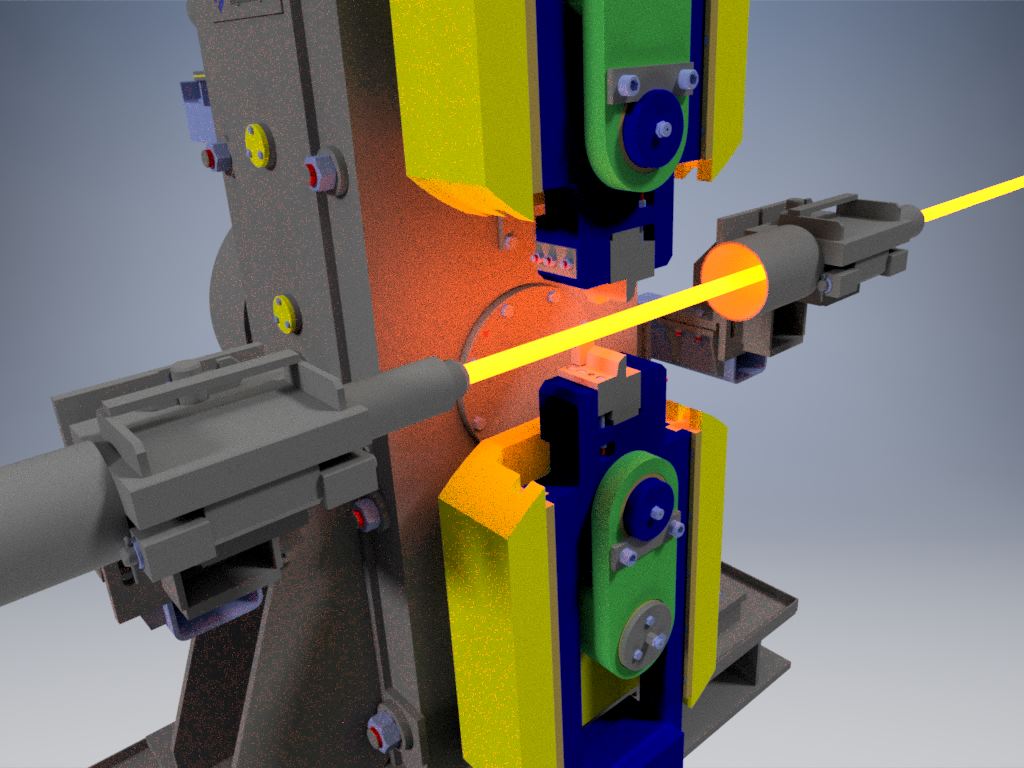

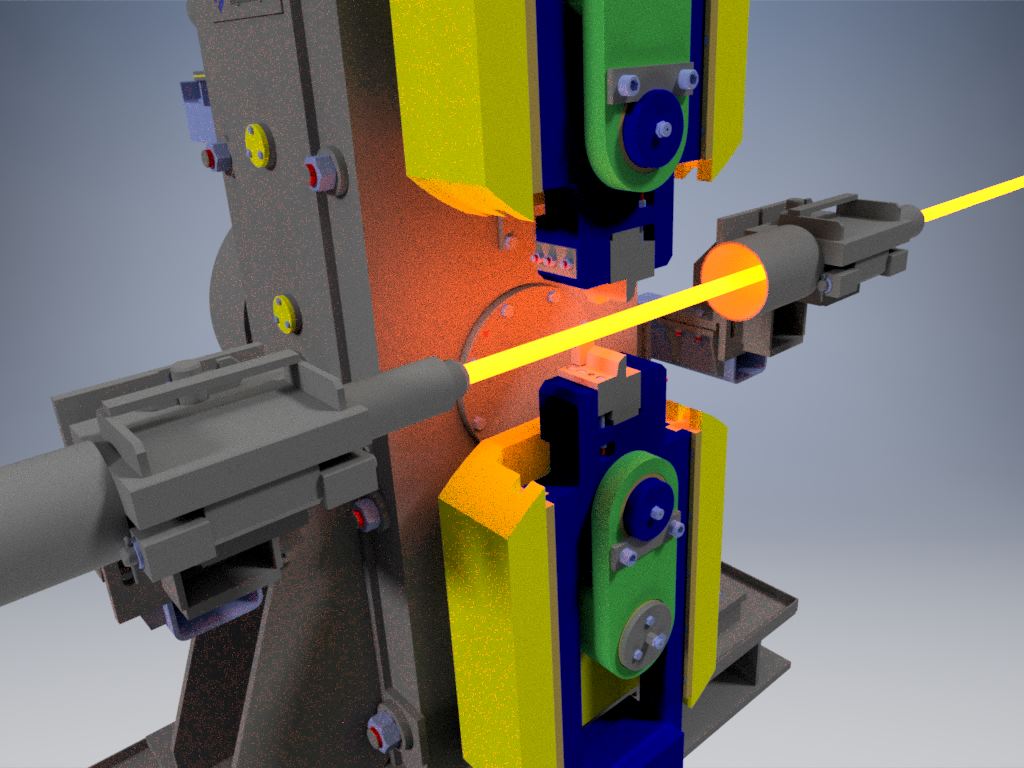

Fast shears for steel bars are designed for small cross sections when working at high speeds (up to 40 m/s). At lower speeds, it is possible to cut rolled products with a larger cross-section. Thus, these shears are suitable for products of any size processed on modern mills for bars.

Due to high frequency of cutting, it is common to install only one pair of shears instead of 2 or 3 cutting machines.

Unlike cutting machines, wear on the cutting blades in shears is minimal.

| Process description | cutting the rod before the cooling section |

| Operating mode | continuous rotating shears with adjustable knives |

| Diameter of workpiece | 8 — 30 mm |

| Rolling speed | 1 — 40 m/s |

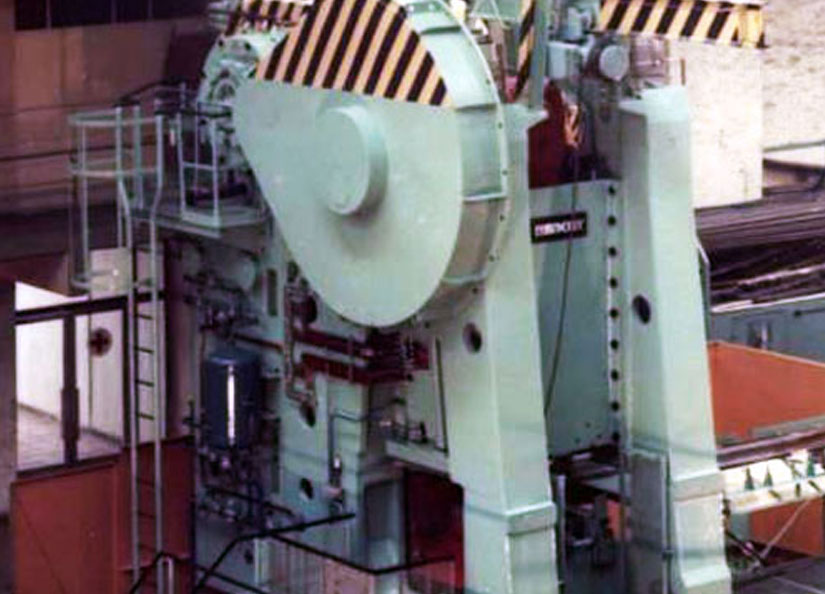

Crank-lever shears

Crank-lever shears are designed in such way that during cutting the knives are positioned perpendicular to the workpiece being rolled.

This type of shears is used for cutting medium and coarse profiles.

Available shear designs

|

Cutting force |

360 kN |

|

Rolling speed |

0.5 — 2.5 m/s |

|

Cutting force |

660 kN |

|

Rolling speed |

0.16 — 1.15 m/s 0.1 — 1 m/s |

|

Cutting force |

1250 kN |

|

Rolling speed |

0.1 — 1 m/s 0.75 — 1.45 m/s |

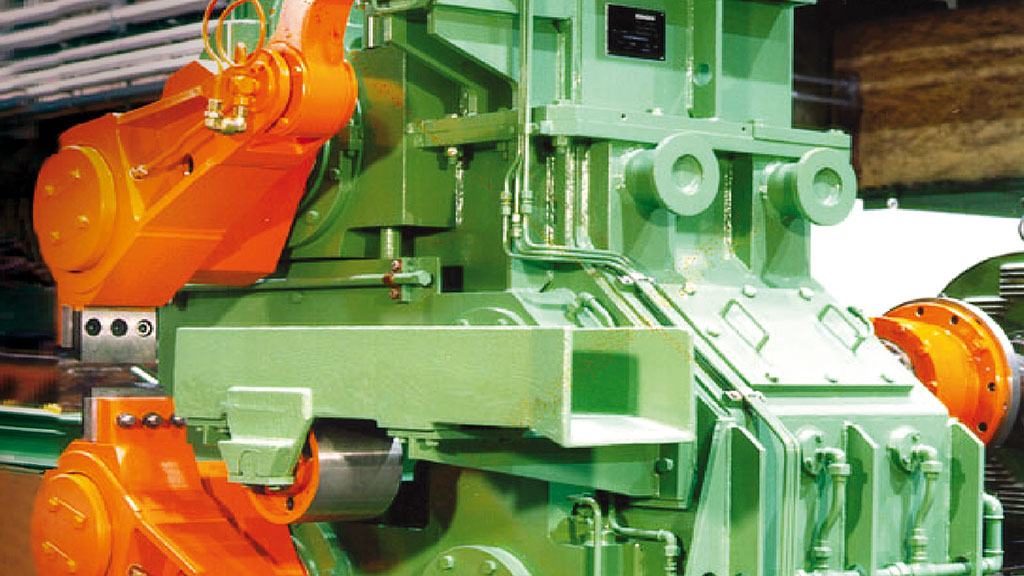

Double crank shears

Double crank shears use profile blades.

They are positioned perpendicular to the workpiece during the cutting.

This type of shears is used for cutting medium and coarse profiles.

Crank shears with two measuring tracks. The first line with one blade, the second line of the axis with three blades per holder.

The design of the blade holder is adapted to the required application, for example:

- One line with one blade: trimming, dividing (for example, along the length of refrigerator), low temperature rolling;

- One line of blades with two blades: trimming, making emergency cuts;

- Multi-blade line: short emergency cut lengths;

-

Two blade lines with additional switch:

- First line: engagement, separation,

- Second line of blades: short emergency cut lengths;

The shears are driven by the pulse generator.

Next, cutting is done into pieces of the selected length.

After the cut the shears stop.

The scraps are removed.

Available shears designs

Number of lanes | 2 |

Cutting force | 200 kN |

Rolling speed | 2 — 5 m/s |

Number of lanes | 1 |

Cutting force | 315 kN |

Rolling speed | 1.9 — 13.3 m/s |

Number of lanes | 1 | 2 |

Cutting force | 360 kN | 360 kN |

Rolling speed | 0.5 — 2.8 m/s | 1.4 — 7.2 m/s |

Number of lanes | 1 | 2 |

Cutting force | 400 kN | 400 kN |

Rolling speed | 1.6 — 16 m/s | 1.4 — 5 m/s |

Number of lanes | 1 |

Cutting force | 580 kN |

Rolling speed | 0.7 — 11 m/s |

Shears for cold profile cutting

Shears are used in hot rolling to trim the front and back ends and also for segment cutting in case of unforeseen circumstances. These shears operate on the start-stop system and are driven either by a pneumatic clutch-brake mounted on the flywheel or by direct drive from DC motor. These shears are controlled using PLC (Programmable Logic Controller) which ensures very precise cut length tolerance.

Refrigerator dividing shears (shears for thermo-mechanically strengthened fittings)

These shears are used to cut the workpiece to the length of the refrigerator (minimum surface temperature about 350 ° C). Dividing shears are usually installed after the hardening line and before entering the refrigerator.

The shears operate on the stop-start system with continuous operation and are driven by a direct drive DC motor. Controlled by a PLC system, a very precise cut length tolerance is achieved.

Rotating shears

Rotating shears are effectively used for trimming the ends of workpieces and also for removing pre-hardened rods in case of emergency. These shears are of continuous rotating type. Typically, these shears are used to cut hot-rolled bars at a significantly reduced speed.

Hot cutting saws

Hot saws are used in hot rolling to cut the section to the desired length and also to trim the front and back ends accurately. These shears are capable of cutting workpieces with profile height from 80 to 600 mm (beam, channel, corner), as well as square and round sections with a section height from 40 to 250 mm. At the moment, there are two types of such saws: pendulum and horizontal.

Features:

- Both open and closed types are available;

- High precision cutting;

- Quick-change device for blade replacement;

- Processes hardened reinforcement and high-alloy steels;

- Can be used with the start-stop drive.