Spare parts

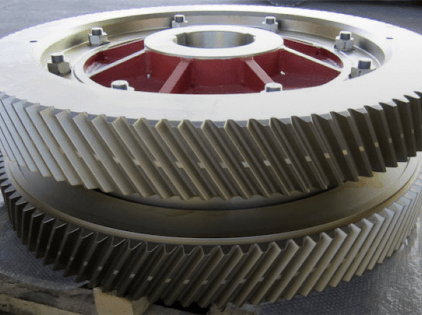

Sket spare parts

Our company takes upon itself the solution of all issues regarding the supply of spare parts for long rolling mills.

We are committed to maintaining the Magdeburg rolling mills' tradition of quality and state-of-the-art technology, and to expanding production through innovation.

Our company supplies machines and equipment with high-quality spare parts and components.

More

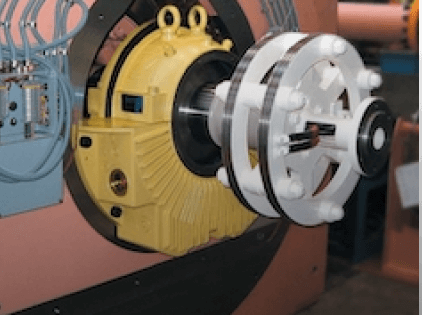

We are committed to maintaining the Magdeburg rolling mills' tradition of quality and state-of-the-art technology, and to expanding production through innovation.

Our company supplies machines and equipment with high-quality spare parts and components.

DANIELI spare parts

More

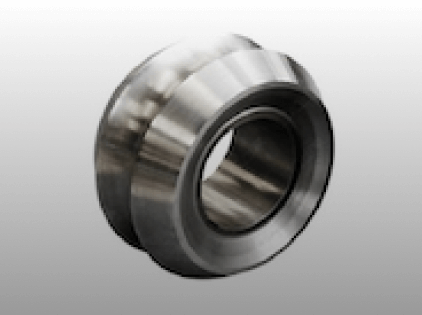

ZOLLERN spare parts

With more than 80 years of experience in the development and production of metal plain bearings and highly developed technology for the production of laminated materials for plain bearings, ZOLLERN is one of the leading manufacturers of such bearings.

Sliding bearings from the ZOLLERN concern are used all over the world in diesel engines on ships, locomotives or stationary installations, as well as in turbines, generators, gearboxes and the wide variety of machines.

More

Sliding bearings from the ZOLLERN concern are used all over the world in diesel engines on ships, locomotives or stationary installations, as well as in turbines, generators, gearboxes and the wide variety of machines.

Rolling rolls, washers, carbide rollers

More

Die holder

The drawing block is the welded structure, it is divided into front and rear cavities. A guide roller is installed at the entry point to ensure that the wire enters the dies. The power to move the roller is provided by a small cylinder, and a corresponding electrical signal is output to the sensor to fine-tune the rate of change.

More

Drawing drums and cones

Manufacturing material: high-carbon steel, rib thickness is no less than 25 mm, polished surface, hardness is 62 HRC to a depth of no less than 5 mm, surface roughness is no less than Ra0.8.

The inner part of the drum is sprayed with ZnAl to prevent the corrosion, the working area is sprayed with a tungsten-cobalt alloy with a hardness of 1200 HV. The guaranteed drum service life is more than 22,000 hours.

More

The inner part of the drum is sprayed with ZnAl to prevent the corrosion, the working area is sprayed with a tungsten-cobalt alloy with a hardness of 1200 HV. The guaranteed drum service life is more than 22,000 hours.