Rolling equipment

Rolling mills

Rolling mills for the production of wire rod with the diameter of 5 to 20 mm at rolling speeds of up to 120 m/s. We use the latest technologies in production of high-speed mono- and multi-block rolling mill lines that are affordable and of high quality.

More

Rolling mill stands

MWE company supplies frameless rolling stands.

To fasten the rolls the following are used:

- Tapered roller bearings with the possibility of radial adjustment of the rolls;

- Cylindrical roller radial bearings combined with axial radial ball bearings for axial adjustment of the rolls.

More

To fasten the rolls the following are used:

- Tapered roller bearings with the possibility of radial adjustment of the rolls;

- Cylindrical roller radial bearings combined with axial radial ball bearings for axial adjustment of the rolls.

Reducers

To ensure increased reliability and the required level of supply for growing industrial production, we have undertaken the significant expansion and increase in capacity.

We have the necessary experience in manufacturing precision reducers using the best equipment that provides the full production cycle. Our team of engineers and metallurgists, as well as state-of-the-art manufacturing and testing facilities, enable us to achieve the level of reliability required for severe operating conditions.

More

We have the necessary experience in manufacturing precision reducers using the best equipment that provides the full production cycle. Our team of engineers and metallurgists, as well as state-of-the-art manufacturing and testing facilities, enable us to achieve the level of reliability required for severe operating conditions.

Hardening systems

APROCS (Advanced Property Control System) APROCS is the temperature control system for rolling mills operating at speeds up to 120 m/s.

Properties of modern wire mills:

- Rolling speed up to 120 m/s;

- Material utilization rate is 90% and above;

- Material yield is more than 96%;

- Good tolerances and minimal nicks on the surface, which increases the market price of products;

More

Properties of modern wire mills:

- Rolling speed up to 120 m/s;

- Material utilization rate is 90% and above;

- Material yield is more than 96%;

- Good tolerances and minimal nicks on the surface, which increases the market price of products;

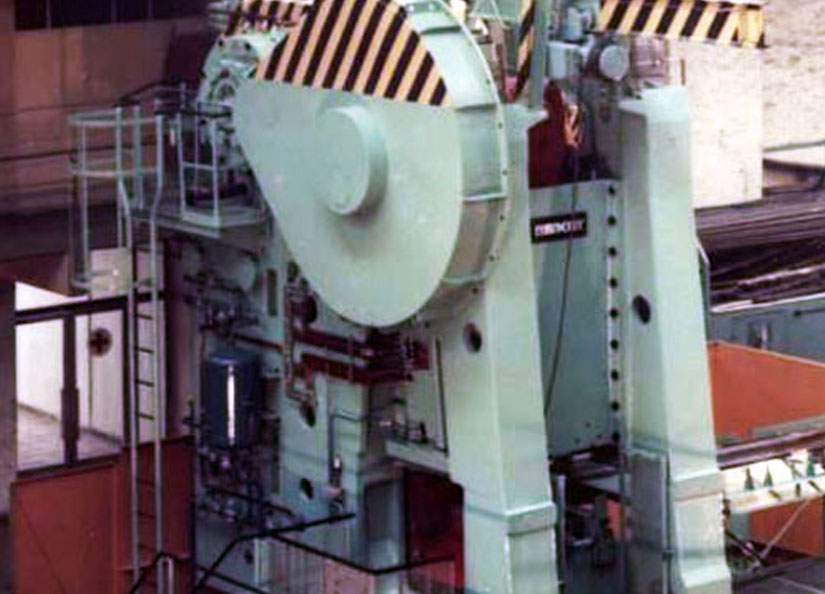

Blades and saws

Various types of shears are widely used in rolling mills.

MWE supplies the following types of shears:

- Flying shears (crank or crank-lever) on a rolling mill;

- Shears for cutting wire rod on high-speed rolling;

- Shears for cutting the workpiece along the length of the refrigerator;

- Shears for cutting rolled products to the length of the finished product:

More

MWE supplies the following types of shears:

- Flying shears (crank or crank-lever) on a rolling mill;

- Shears for cutting wire rod on high-speed rolling;

- Shears for cutting the workpiece along the length of the refrigerator;

- Shears for cutting rolled products to the length of the finished product:

Block rolling mills

Characteristics

Structural elements:

- Strong and compact design;

- Cantilever rolls;

- Rolls located in 450 planes with 900 options for orientation of the stands relative to each other;

- Roll neck with the diameter of 150 mm;

More

Structural elements:

- Strong and compact design;

- Cantilever rolls;

- Rolls located in 450 planes with 900 options for orientation of the stands relative to each other;

- Roll neck with the diameter of 150 mm;

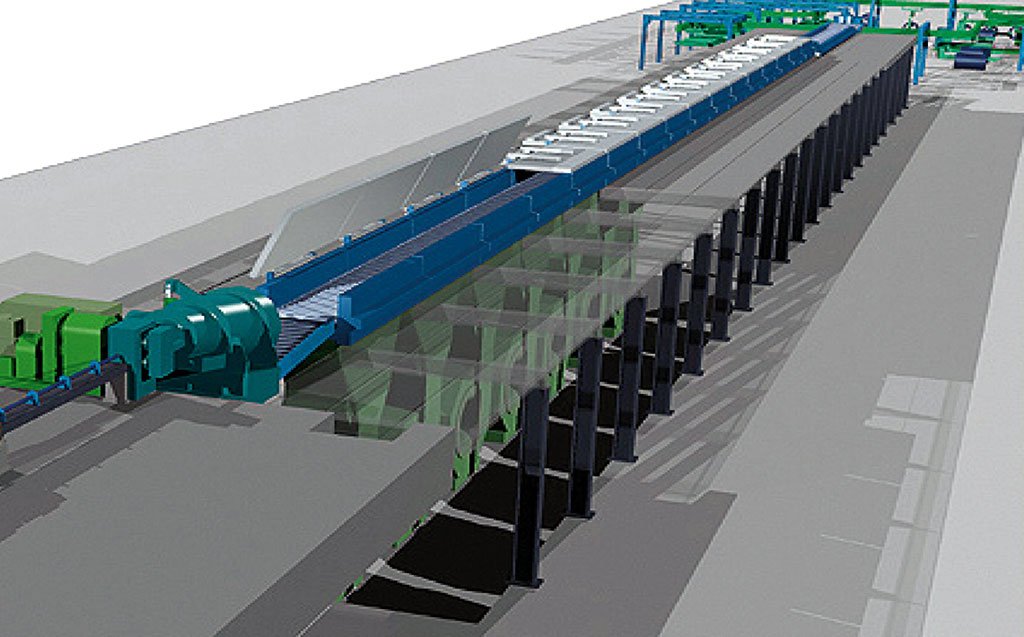

Refrigerators

Complete standardization of mechanical components guarantees consistent quality of the equipment as well as high level of productivity. Depending on different speed requirements, refrigerators can be equipped with lifting decks and natural braking, magnetic braking, or dual-channel and mechanical braking. In some cases, refrigerators are equipped with slow cooling using insulating covers and forced cooling using water spray systems or water tanks. For high-speed rolling modes, a dual-channel or dual-channel cooling system is available.

More

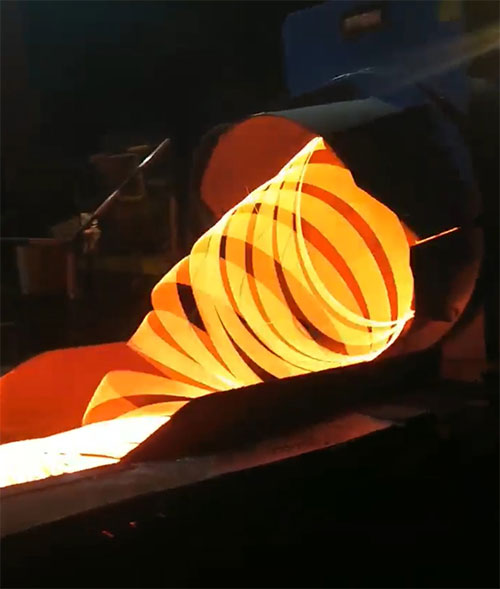

Garrett take-up

Edenborn and Garrett take-up devices produce coils with the vertical axis. The take-up devices are designed to work with rods from 5.5 mm to 50 mm at the rod rotation speed of up to 40 m/s.

The design is compact and durable. The pipes are laid in such a way as to obtain an ideally shaped coil output. Bearings are protected from thermal radiation.

More

The design is compact and durable. The pipes are laid in such a way as to obtain an ideally shaped coil output. Bearings are protected from thermal radiation.

Adjustage

Finishing equipment includes devices for automatic stacking, bundling, strapping, weighing and marking of rolled products

Stackers designed for processing forward and reverse layers are suitable for all types of sections. Forward and reverse layer processing can be mechanical, magnetic or magnetic with high-performance layup.

All stackers have the built-in palletizing function. Packers for round and flat bars are equipped with counting system.

The shape of the packaging can be round, square, rectangular and hexagonal.

More

Stackers designed for processing forward and reverse layers are suitable for all types of sections. Forward and reverse layer processing can be mechanical, magnetic or magnetic with high-performance layup.

All stackers have the built-in palletizing function. Packers for round and flat bars are equipped with counting system.

The shape of the packaging can be round, square, rectangular and hexagonal.

Heavy-duty production

Developed according to the design and specifications of customers for steel, pipe rolling, energy, sugar, and chemical enterprises.

The economic efficiency of the equipment manufacturer largely depends on its own capabilities and the competence of its employees, which, by and large, determines the quality of the equipment and timely delivery.

The complete complex of infrastructure and equipment located on 100,000 sq. m of enterprise working space, designed to perform a wide range of work and tasks. We also specialize in heavy duty horizontal and vertical boring, gear hobbing and many more. Such units work in close connection with overhead cranes with a maximum lifting capacity of 40 tons and a lifting height of 8.5 m. Our facilities are provided with a full backup emergency power supply.

More

The economic efficiency of the equipment manufacturer largely depends on its own capabilities and the competence of its employees, which, by and large, determines the quality of the equipment and timely delivery.

The complete complex of infrastructure and equipment located on 100,000 sq. m of enterprise working space, designed to perform a wide range of work and tasks. We also specialize in heavy duty horizontal and vertical boring, gear hobbing and many more. Such units work in close connection with overhead cranes with a maximum lifting capacity of 40 tons and a lifting height of 8.5 m. Our facilities are provided with a full backup emergency power supply.

СТС turning machines

Processing of rolls on CNC machines:

- Siemens 802D CNC controller with the accuracy of 0.001;

- 1100mm bedplate with 4 guides for better rigidity;

- Large spindle bore and heavy tailstock;

- Hardened and ground guides with Turcite-B coating for longer life.

More

- Siemens 802D CNC controller with the accuracy of 0.001;

- 1100mm bedplate with 4 guides for better rigidity;

- Large spindle bore and heavy tailstock;

- Hardened and ground guides with Turcite-B coating for longer life.

Coil former

The dual-drive rotary drum system guarantees half the response time compared to dual-channel system, so it is suitable for rolling mills with capacity of more than 30 tons per hour;

The drive is installed both at the entrance and at the end of the section, for better control of the operation of the start-stop system of the drum;

No deflection on the inlet and outlet sides, unlike a two-channel system;

Reduced rebar groove size for better control and smooth running at high speeds;

The multi-channel design allows time for the bar to stop before unloading into the refrigerator;

More

The drive is installed both at the entrance and at the end of the section, for better control of the operation of the start-stop system of the drum;

No deflection on the inlet and outlet sides, unlike a two-channel system;

Reduced rebar groove size for better control and smooth running at high speeds;

The multi-channel design allows time for the bar to stop before unloading into the refrigerator;