Hardening Systems

APROCS (Advanced Property Control System) APROCS is the temperature control system for rolling mills operating at speeds up to 120 m/s.

Properties of modern wire mills:

- Rolling speed up to 120 m/s;

- Material utilization rate is 90% and above;

- Material yield is more than 96%;

- Good tolerances and minimal nicks on the surface, which increases the market price of products;

-

Temperature control system in all areas of the rolling mill to achieve reproducible and uniform material properties:

- Rolling in narrow temperature ranges to meet special material requirements,

- Low temperature rolling,

- Controlled cooling for continuous flow heat treatment or for "pre-tuning" material properties,

- Low personnel costs due to high degree of automation,

- Comprehensive software system for the rolling process and subsequent processing of wire rod,

- Continuous development and optimization using the experience gained from operating the large number of rolling mills supplied by MWE,

- An effective tool for saving costs in established production, as well as for achieving the optimal structure of the rolled material and its physical properties.

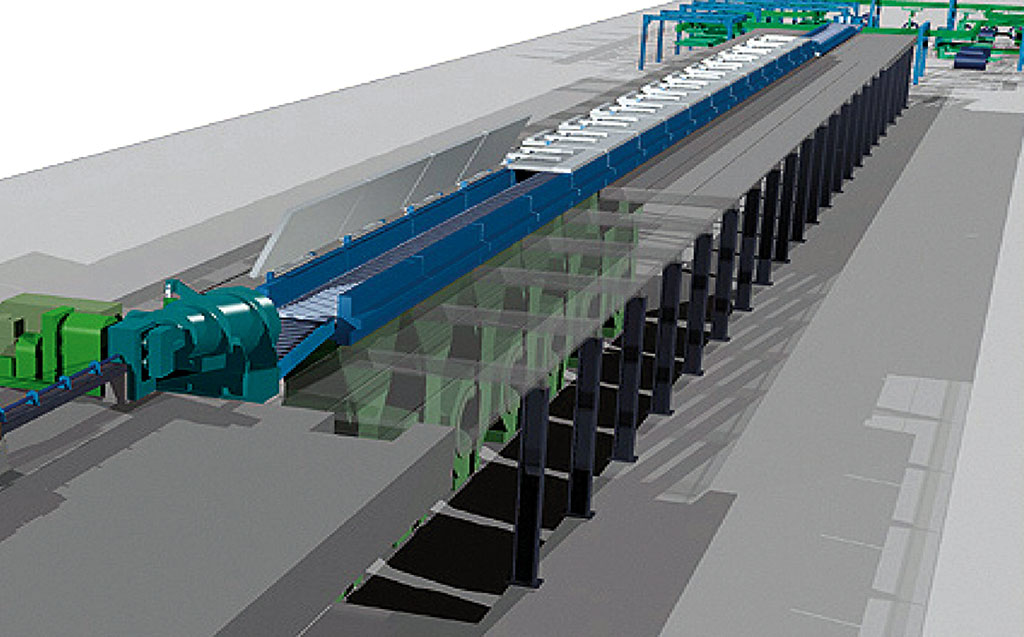

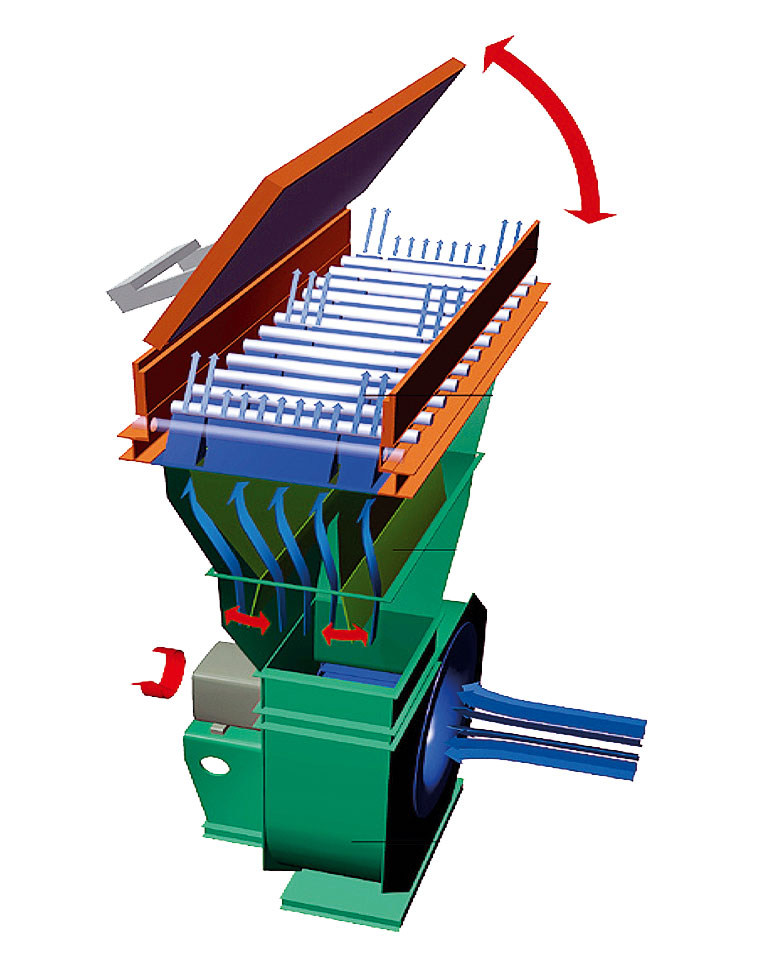

Intermediate cooling before the wire rod block

- Maintaining the desired temperature by regulating water pressure;

- Possibility of rolling with thermal control;

- Improved grain size (fine) of the rolled material;

- Quick-closing valves for high-speed processing of small diameter wire rods, designed to shut off the water supply when the wire reaches the space of the cooling pipe;

- The cooling section is also suitable for other rolling products;

-

High strength indicators:

- Yield strength: 500 N/mm2,

- Tensile strength: 560 N/mm2,

- Elongation: 12%;

-

Other information:

- Final rolling temperature: 950-1050 °C,

- Leveling temperature in the winding layer: 650 °C,

- Water pressure, max.: 1.6 MPa,

- Rolling speed: 80 m/s.

Controlled cooling area

- Slow cooling with intensity <0.3 K/s;

- Accelerated cooling with intensity > 25 K/s;

- Air flow speed on coils > 50 m/s.