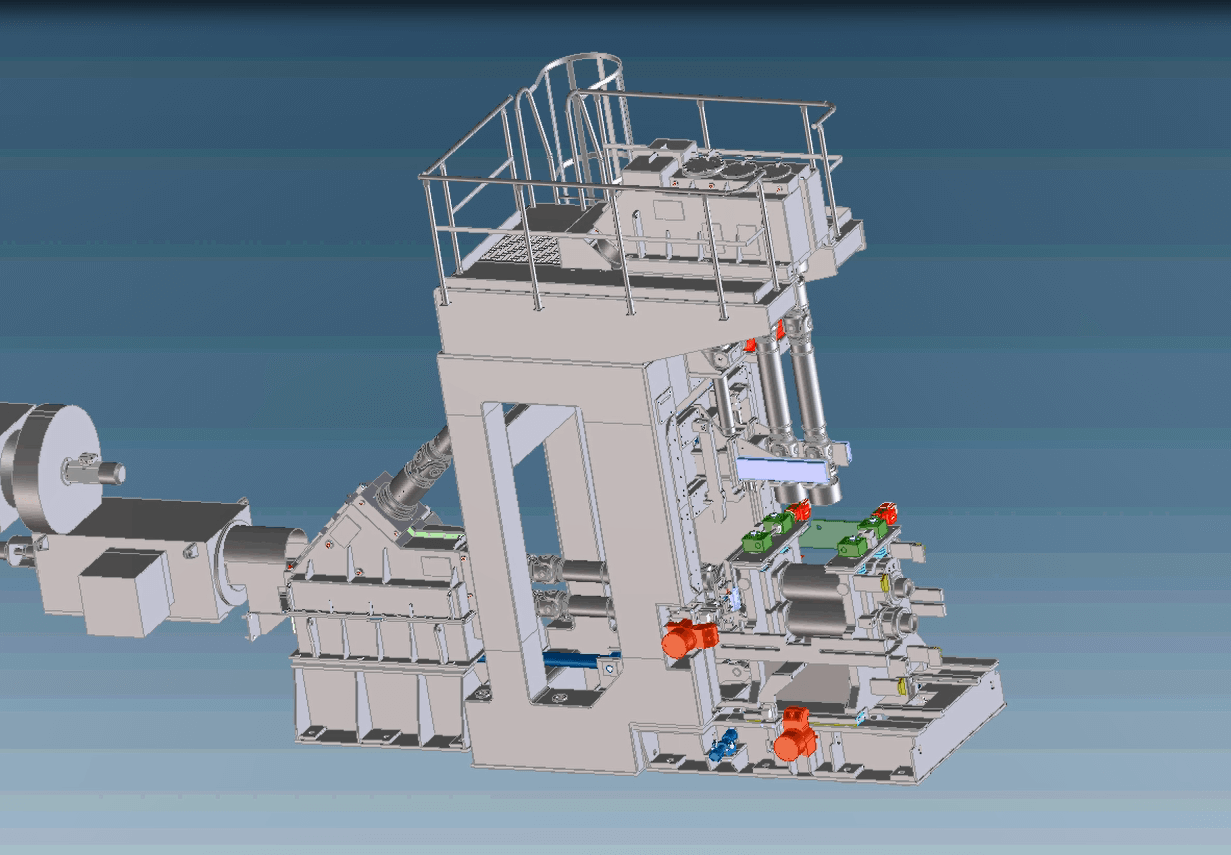

Rolling mill stands

MWE company supplies frameless rolling stands.

To fasten the rolls the following are used:

- Tapered roller bearings with the possibility of radial adjustment of the rolls;

- Cylindrical roller radial bearings combined with axial radial ball bearings for axial adjustment of the rolls.

Thanks to this, rolling stands can be quickly and easily converted.

Our traditionally robust design is added by a guide frame that supports the frame and adjustment gears. Thus, the pads are able to maintain their position under the highest loads.

MWE offers the following types of rolling stands:

-

Double roll stands:

- H-shaped,

- V-shaped,

- assembled into an H/V circuit;

- Triple roll stands;

- Rolling stands of BD type;

-

Double and triple roll stands:

- reversible,

- mobile (only for double roll version);

-

The universal stand can be used as:

- H-shaped

- universal stand system.

Sliding stands

Modern sliding double roll stands are reversible and fully automatic. They represent the innovative solution for roughing and intermediate rolling and mark a new stage in the development of three-roll stands. Features:

- Fixed rolling line with sliding stands for precise alignment with the groove according to passage design, thereby reducing the width of the roller table;

- Improved workpiece processing system;

- Automatic adjustment of the gap between the rolls;

- Simplicity of the cooling system;

- Adjustable feed speed allows to reduce the grip angle.

Universal stands

Modern rolling mills can be used in the wide range of configurations, providing the greatest possible variety of products from the same equipment. Switching from one unrelated product to another is achieved with simple button presses, without the time-consuming procedures required to replace an old-style rolling mill. Convertible stands allow intermediate and finishing lines to be set in both horizontal and vertical positions, based on production requirements.

Features:

- Less than two minutes to change the position;

- Excellent stand rigidity;

- Reduced size of the cooling section;

- System for quick stand replacement without the use of lifting mechanisms.

Universal stands

Such stands alternate with horizontal ones when rolling structural profiles. In addition to horizontal rolls, the stands are equipped with the set of guide rolls for processing flanges.

Features:

- Fast replacement of stands and rolls;

- Prefabricated design, reducing the need for lifting mechanisms;

- Hydraulic vertical and horizontal adjustment of the rolls;

- Maximum rigidity with open-frame design.

Features:

- Less than two minutes to change the position;

- Excellent stand rigidity;

- Reduced size of the cooling section;

- System for quick stage replacement without the use of lifting mechanisms.